[Source: Exide]

Last Updated on October 28, 2007

Performing preventive maintenance on batteries is easy and should occur at least once a month during hot weather and every three months in cold weather. While working with car and deep cycle lead-acid batteries (and corrosion), please wear glasses to protect your eyes in the unlike even of an explosion. Here are some simple steps to maintain your battery:

3.1. Before you start the engine for the first time during the day, check the electrolyte level for non-sealed wet batteries (with filler caps). If above the plates and for all other battery types, check the State-of-Charge (SoC) of the battery. Please see Section 4.4 for more information on determining the SoC. If the battery is not fully charged (100% State-of-Charge), recharge it with an external battery charger in a well ventilated area. Please see Section 9 for more information on charging. This is because State-of-Charge is based on your driving habits. Some vehicle charging systems have been known to consistently undercharge the battery causing an accumulation of lead sulfate, know as sulfation. A gradual build up of sulfation will reduce the capacity of the battery. Periodically fully recharging with an external charger will restore most or all of the battery's capacity. Once per month is recommended during summer and every three months during winter.

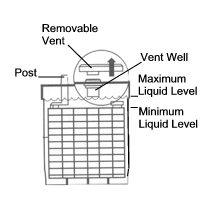

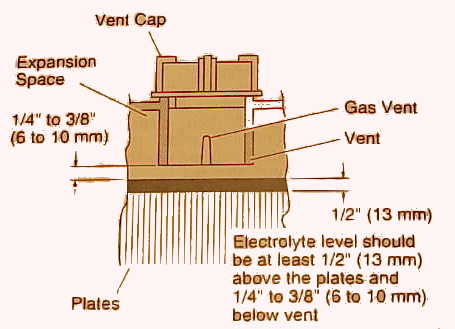

3.2. Checking electrolyte levels of non-sealed (with filler caps) batteries once per month is recommended during summer and every three months during winter. The plates need to be covered at all times to prevent sulfation and reduce the possibility of an internal battery explosion. For non-sealed wet car batteries and small deep cycle batteries (less than 200 amp hours) with low electrolyte levels, recharge the battery first and allow the battery to cool to room temperature. Then add only distilled, deionized or demineralized water to the level indicated by the battery manufacturer or just to the bottom of the filler tubes (vent wells or splash barrels) as shown in the diagram below. On large deep cycle batteries, fill to within 1/4 to 3/8 inch (6 to 10 mm) below the bottom of the filler tubes. Avoid overfilling, especially in hot weather, because the heat will cause the electrolyte to expand and overflow. In an emergency, use rain water. Do not use tap water or water from residential Reverse Osmosis (RO) systems to refill batteries because it could contain chlorine, calcium or magnesium and produce chlorine gas or calcium or magnesium sulfate crystals. These crystals can gradually fill the pores or coat the plates which will reduce the battery's capacity and cause premature failure. State-of-Charge (SoC) readings will be inaccurate immediately after the addition of water, recharges or discharges. Please see Section 4.3 for more information on removing a Surface Charge.

ELECTROLYTE FILL LEVELS FOR SMALL BATTERIES

Less Than 200 AH

[Source: Exide]

ELECTROLYTE FILL LEVELS FOR LARGER BATTERIES

Greater Than 200 AH

[Source: Mountain Top Golf Cars]

To reduce the water consumption for wet batteries, there are special battery caps, for example, Hydocaps, Water-Mizer, etc. that are specifically designed for that purpose. To water the batteries, there are watering systems available that will add water to each battery cell. Please see Watering Systems and Battery Filler Caps for more information. If electrolyte has been spilled, please see Section 9.14 for more information on adding electrolyte or adjusting the Specific Gravity within a cell. If a battery has dried out due to an overcharge, you can try to recovery it by refilling with distilled water and slowly recharging it. It might take several discharge/charge cycles before some or all of the capacity is restored.

3.3. Remove any corrosion, lead oxidation, paint or rust with a brass wire battery brush or with a "ScotchBrite" pad from the terminal's mating surfaces on both ends of each battery cables, battery posts, lugs or terminals, and engine grounding strap connections. For safety, brush the corrosion away from you and wear eye protection. A stiff steel wire brush or sandpaper may damage protective lead plating on copper connectors or terminals. Corrosion is normally a white powdery substance, but could have other colors mixed in with it like gray, yellow or green. Heavy corrosion can be neutralized with a mixture of one pound of baking soda (bicarbonate of soda) to one gallon of warm water. Some folks have been known to use Diet Coke or Pepsi to dissolve corrosion. You are probably thinking why "diet"? Diet is used because it does not contain sugar which will leave a sticky residue. Bare metal to metal mating surfaces are required for very low electrical resistance and good current conductivity.

To prevent corrosion caused by batteries located under the hood, thinly coat the terminals, posts, terminal clamps, lugs and exposed metal around the battery with high temperature and water resistant wheel bearing grease, lithium grease or silicone. Petroleum jelly (Vaseline) or Calcium grease is not recommended for use under the hood because they have a low melting point. Gluing a sacrificial anode, such as a piece of copper to the top of the battery between the posts or using VRLA batteries will prevent or reduce terminal corrosion. Do not use the felt or metal washers between the mating conductive surfaces with General Motors-type side terminals. For car or deep cycle batteries not subject to high temperatures, use "No Oxide A" (or the battery manufacturer's recommended grease) on the posts, lugs, terminals or connectors. Do not use the felt or metal washers between the mating conductive surfaces with side, stud or "L" terminal batteries. Use of some stainless steel alloys and other metal lugs, washers, nuts and bolts have also been known to cause problems with electrolysis and high resistance.

Corrosion is caused by one or more the following:

3.4. Tighten loose hold-down clamps to prevent excessive vibration, battery lugs, terminals and connectors.

3.5. Clean the battery top to eliminate conductive paths created by dried or wet electrolyte and to prevent corrosion.

3.6. Clean the alternator or charging system to allow better heat transfer and check the alternator belts for cracks and correct tension.

3.7. Replace any battery cables (or cable terminals) that are corroding, swelling or damaged with equal or larger diameter cable. If electrical problems are experienced in vehicles with GM's side terminal connectors, check for corrosion inside the positive terminal, lug or connector with the multiple cables. Larger cable and lugs, connectors or terminals are better because there is more surface area and less voltage drop. Please see Exide's Voltage Drop in Cables for additional information.

3.8. Replace the battery if the battery case is bulging, cracked or leaking, especially around "GM" style side terminals.

3.9. Periodically rotate batteries in a bank because the lowest capacity batteries tend to fail first and to insure that the connections are clean and tight.