[Source: Interstate Batteries]

Last Updated on February 5, 2008

7.1.2. Wet Low Maintenance (Sb/Ca)

7.1.3. Wet "Maintenance Free" (Ca/Ca)

7.1.4. AGM [Absorbed Glass Mat] (Ca/Ca) VRLA

7.1.5. Spiral Wound AGM (Absorbed Glass Mat) VRLA

7.1.8. What Are the Differences Between Car, Marine/RV Dual Purpose and Deep Cycle Batteries?

7.1.9. What Are Dual or Multi-battery Systems?

7.1.10. Can Deep Cycle Batteries Used As Starting Batteries?

7.2. CCA (Cold Cranking Amp) Performance

7.3. Reserve Capacity (RC) or Amp Hour (AH) Capacity

7.3.1. Is Capacity Effected By Temperature?

AH Capacity vs. Temperature Graph

7.3.2. How Do I Increase Battery Capacity?

7.3.3. Which is Better, Two 6-volt Batteries in Series or Two 12-volt Batteries in Parallel?

7.3.4. How Do I Increase the Voltage?

7.3.5. How Can I Reduce the Voltage?

7.3.6. Which Weighs More--One 12-volt or Two 6-volt Batteries?

7.3.7. Can I Mix Non-Identical or Old and New Batteries?

7.9. How Do I Size The Components For Backup AC Power?

7.10. How Do I Size Battery Banks?

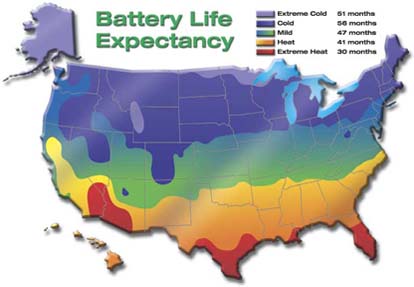

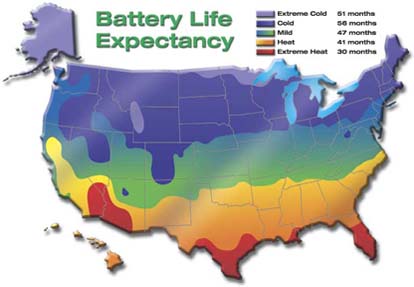

Car battery buying strategy for use in Canada, for example, is different than in the hotter climates found in South Texas. In cold climates, higher CCA (Cold Cranking Amp) performance ratings are more important. In a hot climate, higher RC (Reserve Capacity) or AH (Ampere Hour) capacity ratings are more important than CCA; however, the cranking amp performance sizing should be based on the coldest climate the engine is started in. Do NOT buy a new battery until it is needed because it will sulfate sitting in storage and you will lose capacity and performance. Below is an example of a wet Low Maintenance (Sb/Ca) car battery life expectancy in the United States from Interstate Batteries:

[Source: Interstate Batteries]

The two most common categories of car (including motorcycle and other starting) and deep cycle batteries are Wet (also known as "flooded", "liquid electrolyte", "vented", or "VLA" cell) and Valve Regulated Lead-Acid (VRLA). Within the wet category, the three most common battery types in order of use are Low Maintenance (Sb/Ca), sealed "Maintenance Free" (Ca/Ca), and Standard (Sb/Sb), which are defined in more detail below. In the VRLA category, there are AGM or Absorbed Glass Mat (Ca/Ca), spiral wound AGM, and Gel Cell (Ca/Ca) lead-acid batteries. The one additional category for smaller (typically below 50 AH) deep cycle batteries is SLA (Sealed Lead-Acid) using AGM (Ca/Ca) or Gel Cell (Ca/Ca) VRLA construction. In 2004, approximately 30% of the SLA batteries are produced in China. All VRLA batteries are sealed with a safety pressure relief valve or plug in case of excessive gas pressure build up due to overcharging or overheating.

When selecting a battery type, it is extremely important that you select a battery that will MATCH the voltage outputs of your charging system and application. The easiest way to accomplish this is to replace your battery with the same or compatible type of battery that originally was installed in your vehicle or appliance. If you change your replacement battery to another battery type, you might have to adjust the charging voltage to prevent undercharging or overcharging that could damage or reduce the service life of your new battery. For example, replacing an Original Equipment Manufacturer (OEM) wet sealed "Maintenance Free" (Ca/Ca) with a wet non-sealed Low Maintenance (Sb/Ca) battery (with filler caps) might cause the Low-Maintenance (Sb/Ca) battery to be slightly overcharged and consume more water. If you charge a wet "Maintenance Free" (Ca/Ca) battery with a charging system or charger designed for a wet Low Maintenance (Sb/Ca) battery (with filler caps), you could undercharge the wet "Maintenance Free" (Ca/Ca) battery. Replacing any other non-Gel Cell type of battery with a Gel Cell VRLA (Ca/Ca) battery could overcharge it. If in doubt, replace with an AGM (Ca/Ca) VRLA or spiral wound AGM VRLA battery because they have a wider charging voltage range. Ventilation is required for all lead-acid batteries and good ventilation is mandatory for wet batteries to dissipate the explosive gasses produced during the absorption or equalization charge stages.

Deep cycle batteries are broadly divided into motive, stationary and solar applications. Motive applications are where the battery is discharged in operations that will consume between 20% and 80% of the battery's capacity and then recharged (which is considered to be one cycle). Some examples of motive (also known as "cycling", "leisure" or "traction") applications are for batteries used in recreational vehicles (RV), motor homes, caravans, trailers, boats, wheelchairs, golf carts, solar, floor sweepers, folk lift trucks and other electric vehicles (EV) and typically have between 200-500 cycles per year. Stationary (also known as "float", "reserve", "backup" or "standby") applications are where stationary batteries is used to provide backup or standby power during loss of the primary source of power such as uninterruptible power systems (UPS), emergency lighting systems, security systems, telecommunications systems, etc., and typically have 2-12 cycles per year. If keep below 80 degrees F (26.7 degrees C), stationary batteries have longer service lives than motive batteries with thicker plates due to less being used. They also cost more than motive batteries. The chargers for stationary deep cycle batteries are different from car and motive deep cycle batteries and normally have three stages--bulk, float and equalize. Please see Section 9.1 for more information on charging and charging stages. Solar or photo voltaic batteries are special purpose and used for motive (traction) or stationary (stand-by) applications.

Non-sealed wet Standard (Sb/Sb), wet Low-Maintenance (Sb/Ca), AGM (Ca/Ca) or Gel Cell (Ca/Ca) VRLA batteries with pasted, tubular or Manchester ("Manchex") positive plates or Spiral Wound AGM VRLA batteries are recommended for motive deep cycle applications. Non-sealed wet Standard (Sb/Sb), wet Low-Maintenance (Sb/Ca), wet "Maintenance Free" (Ca/Ca) batteries with pasted or solid (Planté) positive plates are recommended for stationary applications. For more information about deep cycle batteries, please see Allan Tarvid's article Fishing for the Right Battery, Wind & Sun's Ultimate Deep Cycle Battery FAQ and Zen and the Art of Choosing a Deep Cycle Battery.

Wet deep cycle batteries, such as marine/RV, leisure and some golf cart, that use pasted positive plates are less expensive to manufacturer and have fewer life cycles and shorter service lives at 50% average Depth-of-Discharge (DoD) level than the deep cycle batteries with solid (Planté), tubular or Manchester (or "Manchex") positive plates. They also have significantly fewer life cycles at the 80% average DoD level. The major disadvantage of AGM (Ca/Ca) or Gel Cell (Ca/Ca) VRLA deep cycle batteries are their high initial cost (up to three times over the cost of a wet Standard (Sb/Sb) batteries), but arguably can have an overall lower total cost of ownership due to a longer service life, no "watering" and other labor costs, and faster recharging. The total cost of ownership should be considered when buying deep cycle batteries. There is a cost comparison for some popular wet solar deep cycle batteries on THE SOLAR BiZ Web site at http://www.thesolar.biz/Cost_Table_batteries.htm.

Wet Standard or "Conventional" (Sb/Sb) non-sealed lead-acid batteries (with filler caps) have Lead-Antimony (Sb) positive and Lead-Antimony (Sb) negative plates and have been commercially available for almost 100 years. In 1915, the Willard Storage Battery Company introduced sealed hard rubber cases that made car batteries practical. Examples are wet deep cycle batteries from Surrette/Rolls, Trojan, U.S. Battery, etc. They have a:

For these reasons, they have almost been completely replaced by wet Low Maintenance (Ca/Sb) batteries for high temperature underhood starting applications, but are still used for many Marine/RV, solar, golf cart, etc. deep cycle applications. Wet Standard (Sb/Sb) batteries are generally the least expensive lead-acid batteries per amp hour of capacity.

7.1.2. Wet Low Maintenance (Sb/Ca)

The wet (or "flooded" cell), non-sealed Low Maintenance batteries (with filler caps) have Lead-Antimony (Sb) positive and Lead-Calcium (Ca) negative dual alloy or hybrid plate formulations. They have most of the same characteristics as a wet Standard (Sb/Sb) batteries, except they can better handle the higher underhood heat when used in starting applications. Some battery manufacturers, such as Johnson Controls, build "North" and "South" car battery versions to make up for the differences in cold and hot climates. Some also construct special car batteries that have a higher tolerance to heat by changing plate or connecting strap formulations or providing for more electrolyte. For off highway applications in motorcycles, trucks, Recreational Vehicles (RVs), motor homes (or caravans), 4x4s, vans or SUVs (Sport Utility Vehicles), some battery manufacturers build "high vibration", "heavy duty", "commercial", or "Marine/RV" battery versions designed to reduce the effects of moderate vibration. A wet Low Maintenance (Sb/Ca) car or deep cycle battery will typically cost a little more than a similar sized wet Standard (Sb/Sb) battery and is the most common lead-acid battery is use today.

7.1.3. Wet "Maintenance Free" (Ca/Ca)

Wet "Maintenance Free" batteries have a Lead-Calcium (Ca) positive and Lead-Calcium (Ca) negative plate chemistry or formulation, for example, Johnson Controls [formally Delphi], General Motor's ACDelco, or East Penn. They are available in non-sealed sealed (with removable filler caps) and sealed (with non-removable filler caps) versions. The non-sealed versions are recommended for use in hot climates, so lost water can be replaced. The advantages and disadvantages of wet "Maintenance Free" (Ca/Ca) car and deep cycle batteries over wet Low Maintenance (Sb/Ca) are:

However, the versions with "GM" side terminals are more prone to terminal seal leakage due to over-tightening, incorrect terminal bolt length, or vibration from short battery cables. Please see Section 7.5 for more information on terminal types. They are also more susceptible to deep discharge ("dead" or "flat" battery) failures due to increased shedding of active plate material and development of a barrier layer between the active plate material and the grid metal. If a wet "Maintenance Free" (Ca/Ca) battery is sealed, distilled water can not be added when required. For that reason, in hot climates, using non-sealed wet batteries (with filler caps), so distilled water can be added, is highly encouraged. For passenger compartment or trunk battery locations, using a sealed AGM (Ca/Ca) VRLA battery is recommended. Wet "Maintenance Free" (Ca/Ca) batteries are generally little more expensive than wet Low Maintenance (Sb/Ca) batteries.

7.1.4. AGM [Absorbed Glass Mat] (Ca/Ca) VRLA

Sealed Absorbed Glass Mat (Ca/Ca) VRLA car and deep cycle batteries (also know as "starved electrolyte" or "dry") have a very fine fiber Boron-Silicate glass mat between their flat Lead-Calcium positive and Lead-Calcium negative plates. The AGM battery was invented in 1980 and first used in military aircraft in 1985. They have all of the advantages of the "Maintenance Free" (Ca/Ca) batteries plus:

Relocating the vehicle's starting battery to the passenger compartment or trunk is becoming more popular because vehicle manufacturers want to extend their "bumper-to-bumper" warranty periods, to avoid underhood temperature extremes, to provide more weight in the rear, or to save underhood space. Use a vented wet battery or GRT (Gas Recombinant Technology) AGM (Ca/Ca) or Gel Cell (Ca/Ca) VRLA battery. GRT simply means that 90% or more of the gasses are recombined back into water during recharging and contained within each cell and special venting is not required. AGM (Ca/Ca) VRLA batteries are more expensive than wet "Maintenance Free" (Ca/Ca) batteries. Some AGM (Ca/Ca) batteries, for example Concorde, can be equalized. They will accept all the power that a charging system will produce. This means if you are using an alternator sized at 25% (or less) of the capacity of a deep cycle battery bank, it is possible to overheat an air cooled alternator and burn it up during a long bulk charging phase. For large capacity deep cycle battery banks, using a high output alternator, voltage regulator with an alternator temperature sensor or water cooled alternator is highly recommended. A thermally protected alternator should not exceed 33% of the capacity of the battery bank being charged.

You can expect AGM (Ca/Ca) VRLA starting batteries to the $80 to $100 range as more competition occurs. Examples of sealed AGM (Ca/Ca) VRLA batteries are Concorde's Lifeline, EnerSys' Odyssey, or East Penn. An AGM (Ca/Ca) battery can normally replace a wet Low Maintenance (Sb/Ca) or wet "Maintenance Free" (Ca/Ca) battery, but a wet Low Maintenance (Sb/Ca) battery normally cannot replace an AGM (Ca/Ca) VRLA battery without adjusting the charging voltages. 36-volt AGM (Ca/Ca) starting batteries with 14/42-volt dual or 42-volt electrical systems offered by some of the premium car manufacturers starting in the 2003 model year. In the near term, expect to see more sealed AGM (Ca/Ca) batteries replacing wet Low Maintenance and wet sealed "Maintenance Free" lead-acid batteries. Nickel-Metal-Hydride (NiHM) and Lithium Ion (LiIon) batteries and Super Capacitors will used in hybrid and electric vehicle automotive applications, which might eventually be replaced by fuel cells in the next 10-20 years. Please see Collyn Rivers' article Absorbed Glass Mat Batteries for more information on AGM batteries.

7.1.5. Spiral Wound AGM (Absorbed Glass Mat)VRLA

For excessive vibration applications, in off-road operation, or extreme conditions, it is best to use a spiral wound AGM VRLA (Valve Regulated Lead-Acid) car or deep cycle battery because there is no shedding of active plate material since the plates are immobilized. In addition, they also use GRT (Gas Recombinant Technology) and have all of the characteristics of the AGM (Ca/Ca) VRLA batteries with Lead-Calcium positive and Lead-Calcium spiral wound plates plus:

Examples of spiral wound AGM VRLA batteries are Johnson Controls' Optima, Exide's Select Orbital or Maxxima, or EnerSys' Cyclon. Typically spiral wound AGM car batteries cost between $90 and $150 and deep cycle versions cost more.

SPIRAL WOUND AGM BATTERY

[Source: Optima]

Wet marine/RV batteries are available in three different versions--starting, "dual purpose", and deep cycle. The wet "starting" marine/RV battery is basically a wet car (or starting) battery with carrying handles and stud or combination terminals and designed for high current and shallow discharges (up to 5% Depth-of-Discharge). It maybe ruggedized to be more resistant to vibration and shock than an automobile battery. The battery's construction, separator thickness and material, plate thickness and plate composition will all determine a battery's ability to withstand vibration. Securing the battery to reduce the vibration will increase it's service life.

The wet "dual purpose" marine/RV battery is a compromise between a starting and deep cycle battery that is specially designed for high vibration in marine/RV applications. It is generally are more expensive than a starting battery. The "deep cycle" marine/RV battery is designed for deep discharge applications, such as a running a trolling motor. Marine "starting", "dual purpose", or "deep cycle" batteries can have wet Standard (Sb/Sb), wet Low Maintenance (Sb/Ca), or wet "Maintenance Free" (Ca/Ca) plate formulations. Please beware of marine/RV batteries that are cheap, because they are often car batteries with handles and stud or combination terminals. A marine/RV "deep cycle" or "dual purpose" battery will work as a starting battery if it can produce enough current to start the engine. Good ventilation is required for all wet (or "flooded") batteries to dissipate the gasses produced during charging. For saltwater applications, use ONLY sealed AGM (Ca/Ca) or Gel Cell (Ca/Ca) VRLA batteries to prevent the formation of DEADLY chlorine gas if battery electrolyte is mixed with saltwater.

Sealed Gel Cell (Ca/Ca) VRLA (Valve Regulated Lead-Acid) deep cycle batteries also use GRT (Gas Recombinant Technology) and were invented in 1934 by Otto Jache and commercially introduced by Sonnenschein in 1957. They use a thickening agent like fumed silica gel to immobilize the electrolyte instead of a liquid electrolyte like wet batteries. Gel Cell batteries have a lot of the same advantages and disadvantages of AGM (Ca/Ca) VRLA batteries and use Lead-Calcium positive and Lead-Calcium negative plate formulations. When comparing Gel Cell (Ca/Ca) to AGM (Ca/Ca) and Spiral Wound AGM batteries, Gel Cells will typically:

The ideal ambient temperature for a Gel Cell (Ca/Ca) battery is 72° F (22.2° C). Examples of Gel (Ca/Ca) batteries are Sonnenschein, East Penn, MK, Exide, etc.

For some considerations of replacing flooded batteries with Gel Cell (Ca/Ca) or AGM (Ca/Ca) VRLA batteries, please read David Eidell's IMPORTANT NOTE ABOUT THE SUITABILITY OF ABSORPTIVE GLASS MAT (AGM) AND GELLED ELECTROLYTE BATTERIES IN RV'S or Collyn Rivers' ABSORBED GLASS MAT BATTERIES. For a more detailed comparison, read an article written by Constian von Wentzel, Comparing Marine Battery Technologies.

7.1.8. What Are the Differences Between Car, Marine/RV "Dual Purpose", and Deep Cycle Batteries?

Car and marine/RV starting batteries are specially designed with thinner (.04 inch or 1.02 mm) and more porous plates for a greater surface area to order produce the high current required to start an engine. They are engineered for up to 5,000 shallow (to 3% Depth-of-Discharge) discharges, which is over four engine starts per day. Starting batteries should NOT be discharged below 10% Depth-of-Discharge (DoD). They use sponge lead and expanded metal grid paste plates rather than solid lead plates. Marine/RV "dual purpose" batteries are a compromise between a car and deep cycle battery and are designed for starting and prolonged discharges at lower amperage that typically consumes between 20% and 50% of the battery's capacity. The plates are thicker that in starting batteries, but thinner than in deep cycle batteries. Motive and stationary deep cycle batteries have much thicker (up to .25 inch or 6.35 mm) plates, thicker grids, more lead, and weight more than car batteries of the same size. They also have a slightly higher Specific Gravity and are normally discharged between 20% and 80% Depth-of-Discharge at a lower amperage. Deep cycle batteries will typically outlast two to ten car batteries in a deep cycle application.

7.1.9. What Are Dual or Multi-battery Systems?

For special high electrical load requirements, such as an emergency vehicles, RVs, motor homes, caravans, boats, or vehicles with snow plows, electric winches, high power audio or lighting systems, etc., both car and deep cycle batteries are often used. A car battery is normally used to start the engine and motive deep cycle (or leisure) batteries that are the same battery type (plate chemistry) as the car battery are used to power the electrical accessories. The batteries are usually connected to dual charging systems or a Schottky diode isolator (or combiner), dual output alternator, isolation relay or A/B switch to keep the starting battery from becoming discharged when using the auxiliary deep cycle batteries. When the charging system is running, the batteries are automatically recharged (except with the manual relay or A/B switch) with most of the current flowing to the battery with the highest Depth-of-Discharge. Isolator sizing is important and should be larger than the combined current sources on each side of the isolator. For example, if a diode isolator is used with a 40 amp "shore" power battery charger and a 100 amp alternator, then the diode rating should be at least 140 amps. If a relay or A/B switch is used and the charger is 100 amps, but there is a load of 300 amps, then the isolator need to be rated at the larger of the two or 300 amps or more. The wiring with fuses also needs to be rated to carry at least this much current with a 5% or less voltage drop at full current.

Ralph Scheidler at Sure Power has written an excellent, easy to understand, free e-booklet, Introduction to Batteries and Charging Systems, about multi-battery applications. It is available online at http://www.surepower.com/pdf/ebr_int.pdf. A common deep cycle application in recreational vehicles is using a DC to AC inverter, which is used to convert 12 volts DC to 120 (or 240) VAC power. It takes between 12 and 14 amps of 12-volt DC power to make one amp (or 120 watts) of 120 VAC power (or one-half amp or 120 watts of 240 VAC power), so deep cycle batteries or vehicle charging systems should be used to power inverters and NOT starting batteries. Some multi-battery systems can get extremely complex.

Some of the following risks are undertaken when a discharged deep cycle battery (or bank) is connected in parallel to the starting battery without using a diode isolator:

Diode isolation systems, unless voltage compensated, lose between .6 and 1.6 volts across each diode. There is also loss in wring that will reduce the charging voltage to the battery. Regardless of what isolation method is used, apply the battery manufacturer's temperature compensated charging voltages directly across the respective battery terminals to optimize the battery's capacity and overall service life. This is especially important when mixing battery types and can be accomplished in several different ways depending on the charging system. For example, if the voltage regulator is equipped with a sense wire, it can be connected to the output of the diode isolator or positive battery terminal or the internal voltage regulator can be replaced with an adjustable or a "smart" voltage regulator. Individual battery or battery bank voltage regulators can be used downstream of the isolator. If the voltages are not correct, then battery under or overcharging can occur and cause premature failures. If the deep cycle battery bank is located within a living or passenger area, using AGM (Ca/Ca) or Gel Cell (Ca/Ca) VRLA batteries is highly recommended for safety reasons.

7.1.10. Can Deep Cycle Batteries Used As Starting Batteries?

Some things to consider in using a motive deep cycle (or Marine/RV Dual Purpose) battery as a starting battery are:

If the answer to these questions is yes, then it should work. However, it might crank the engine slower or not last as long as a starting battery for this application, due of the high under hood temperatures and shallower discharges. There have been other examples where a wet motive deep cycle batteries have lasted over ten years. Fully recharge the deep cycle battery with an external charger first and have it tested at an auto parts or battery store. If good, then try it and monitor the SoC and electrolyte levels for the the first few months for proper charging. If the State-of-Charge is continuously low, the battery is being undercharged and sulfate will gradually build up, thus reducing the capacity of the battery and causing it to prematurely fail. If it is using a lot of water, then it is being overcharged and can prematurely fail.

7.2. CCA (Cold Cranking Amp) Performance

If the battery is to used in a starting application, Cold Cranking Amp (CCA) performance is the second most important consideration; otherwise, for deep cycle applications, please skip this section and go to Section 7.3. Reserve Capacity (RC) or Amp Hour (AH) Capacity. The battery's CCA performance rating should meet (or just exceed) the vehicle manufacturer's recommendation or is best suited for the coldest temperatures encountered in your climate. BCI's definition of CCA is the discharge load measured in amps that a new, fully charged battery, operating at 0° F (-17.8° C), can deliver for 30 seconds while maintaining the voltage above 7.2 volts. Car and Marine Starting batteries are sometimes advertised by their CA (Cranking Performance Amps) measured at 32° F (0° C), MCA (Marine Cranking Amps) measured at 32° F (0° C), or HCA (Hot Cranking Amps) measured at 80° F (26.7° C). These measurements are not the same as CCA. Do not be misled by the higher CA, MCA or HCA ratings. To convert CA or MCA to CCA, multiply the CA or MCA by 0.8. To convert HCA to CCA, multiply HCA by 0.69. The British and International Electrotechnical Commision's definition of CCA are cranking for 180 seconds and down to 8.4 volts at 0° F (-17.8° C) and for 60 seconds and down to 8.4 volts at 0° F, (-17.8° C), respectively.

To start a four cylinder gasoline engine, you will need approximately 600-700 CCA; six cylinder gasoline engine, 700-800 CCA; eight cylinder gasoline engine, 750-850 CCA; three cylinder diesel engine, 600-700 CCA; four cylinder diesel engine, 700-800 CCA; and eight cylinder diesel engine, 800-1200 CCA. Bruce Bowling and Al Grippo have written a very handy Battery Cold-Cranking Amp Estimation calculator which can be found at http://www.bgsoflex.com/cca.html. To convert CCA, a SAE (Society of Automotive Engineers) standard, to an EN (now known as ETN), IEC, DIN or JIS standard, please refer to the Conversion Table at www.cadex.com/_downloads/_support/SpectroQuickRefGuide.pdf from Cadex or http://web.archive.org/web/20050517213320/http://www.midtronics.com/manuals/power_sensor105_manual.pdf from Midtronics.

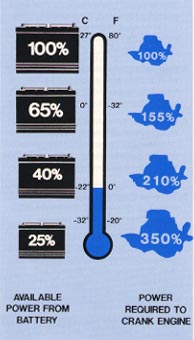

In hot climates, buying car or marine starting batteries with double or triple your vehicle's cold cranking amp requirements is a waste of money because the extra amps will not be used. A starter motor will only demand what it needs to operate. However, in extremely cold climates a higher CCA rating is better, due to increased power required to crank a sluggish engine and the inefficiency of a cold car battery. As car batteries age, they are also less capable of producing as much CCA as when they were new. According to BCI (Battery Council International), diesel engines require 220% to 300% more current than their gasoline counterparts and winter starting requires 140% to 170% more current than during summer. These increased requirements are accounted for in the OEM (Original Equipment Manufacturer) CCA performance recommendations .

CCA PERFORMANCE vs. TEMPERATURE

[Source: Exide]

If more CCA performance is required, two identical 12-volt starting batteries can be connected in parallel or two identical larger CCA 6-volt starting batteries can be connected in series. Please refer to the diagrams in Section 7.3 below for more information about connecting batteries in parallel or series. If you connect two 12-volt batteries in parallel and they are identical in type, age and capacity, you can potentially double your original CCA performance. If you connect two in series that are not the same type or capacity, the battery (or cell) with the lowest capacity will overcharge or over discharge.

7.3. Reserve Capacity (RC) or Amp Hour (AH) Capacity

For car batteries, an equally important consideration to CCA is the Reserve Capacity (RC) or Amp Hour (AH) endurance ratings because of the effects of increased parasitic (ignition key off) loads while long term parking, power demands during short trips and emergencies. Endurance is defined by Eurobat as the actual combination of the energy content stored in a battery and the rate which the battery is discharged over the life time. RC is the number of minutes a fully charged battery at 80° F (26.7° C) can be discharged at a constant 25 amps until the voltage falls below 10.5 volts. European and Asian starting and deep cycle batteries are usually rated in Amp Hours (AH). To convert RC to AH (or AH to RC), check the battery manufacturer's capacity specifications. More RC (or AH) is better in every case. In a hot climate, if your car has a 360 OEM cold cranking amps requirement, then a 400 CCA rated battery with 120 minutes of RC and more electrolyte for cooling would be more desirable than one with 600 CCA with 90 minutes of RC. There is also a relationship between the weight of the battery and the amount of RC (or AH). The heavier the battery, the more lead is has and potentially a longer service life.

For deep cycle batteries, important considerations are will the Ampere-Hour (AH) rating meet or exceed the requirements based on your application? Peukert Effect? and how much weight you can carry? Most deep cycle batteries are normally rated in number of hours it take to discharge a fully charged battery to 10.5 volts in 20 hours at 80° F (26.7° C), denoted as "C/20". Discharge rates of 100 hours (C/100), 10 hours (C/10), 8 hours (C/8) or 6 hours (C/6) are also common ratings. When comparing amp hour capacities of deep cycle batteries, use the same discharge rating periods which can be obtained form the battery manufacturer. For example due to the Peukert Effect, the same wet deep cycle battery with the amp hour capacity of 240 discharged over 20 hours could have a capacity of 176 amp hours when discharged over six hours or 115 amp hours when discharged in one hour. Within a BCI Group Size, the battery with higher AH (or RC) will tend to larger in physical size, have longer service lives and weigh more because of thicker plates and more lead than car batteries.

PEUKERT EFFECT In 1897, W. Peukert determined that the higher the discharge rate (or fewer hours the battery is fully discharged in), the lower the capacity due to the Peukert Effect or "the shrinking battery effect" and to the internal resistance of the battery. Good examples of the Peukert Effect on deep cycle battery capacities at various discharge rates can be found at http://www.usbattery.com/ on their capacity specifications page. The actual formula is T=C/IN where N is the Peukert Number used for the specific battery to more accurately calculate the discharge time. For a detailed explanation of the calculation, please see Steve Gibson's article, An in depth analysis of the math behind Peukert's Equation (Peukert's Law). The Peukert Number generally is in a range of 1.05 to 1.4, with 1.05 the best performing battery due to less internal resistance. A Peukert Number calculator and some specific examples of batteries can be found on Eve's Battery Page at http://www.geocities.com/CapeCanaveral/Lab/8679/battery.html.The effects are shown in Constantin von Wentzel's graph below. A good analogy on the Peukert Effect and be found at Ample Power on http://www.amplepower.com/pwrnews/beer/. Another Peukert calculator is included on http://home.hetnet.nl/~marcellebarion/epeukert.html.

|

Normally the best buy will be the heaviest battery that best suites your application, physical size requirements and that has the lowest cost (including maintenance) for the total amount of power it will produce over it's service life. Larger is better!

7.3.1. Is Capacity Effected By Temperature?

Temperature matters! The following graph from Concorde shows the effects of temperature on the amp hour capacity on their AGM (Ca/Ca) battery:

PERCENT CAPACITY vs. TEMPERATURE

[Source: Concorde]

7.3.2. How Do I Increase Battery Capacity?

If more amp hours (AH) or Reserve Capacity (RC) are required, there are normally three ways to accomplish this:

7.3.2.1. Two (or more) 12-volt batteries can be connected in parallel, should be identical and connected exactly as shown in the diagram below for best results. If you connect two 12-volt batteries in parallel and they are identical in type, age and capacity, you can more than double your original capacity due to the Peukert Effect. If you connect two or more batteries (or battery banks) in parallel that are not the same type or capacity, proper charging can become more difficult. Using a properly sized "smart" charger is highly recommended. To better balance the voltage, please take special note of the connections from the POSITIVE (+) battery terminals to a single positive (+) distribution point and the connections from the NEGATIVE (-) battery terminals to a single NEGATIVE (-) distribution point. All of the interconnecting leads between the battery terminals and distribution points need to be exactly the same wire size and length so the voltage will be the same. The number of batteries (or strings of batteries) in parallel should be limited to four. For more information on connecting batteries in parallel, please see Chris Gibson's excellent article How to correctly interconnect multiple batteries to form one larger bank. Chris' article goes into detail on why incorrectly connecting batteries in parallel will cause loss of capacity resulting in premature battery failures.

12-Volt Batteries In Parallel

7.3.2.2. Two identical larger capacity six-volt batteries can be connected in series by connecting the NEGATIVE (-) terminal of Battery One to the POSITIVE (+) terminal of Battery Two. Do not mix non-identical battery types, battery manufacturers or capacity in series because the battery (or cell) with the lowest capacity will overcharge or over discharge. Batteries in series are much easier to correctly charge, offer higher reliability due to few number of cells, but are limited to the lowest capacity battery (or cell) in the series.

Batteries In Series

7.3.2.3. Two identical larger capacity six-volt batteries can be connected in series by connecting the NEGATIVE (-) terminal of Battery One to the POSITIVE (+) terminal of Battery Two to make a "12-volt battery". Two (or more) "12-volt batteries" can be connected in parallel. The combination is referred to as a series-parallel bank. Please see the recommendations for connecting batteries (or battery banks) in parallel in Section 7.3.2.1 above.

6-Volt Batteries In Series-Parallel

When connected as exactly shown in the above diagrams, the batteries will better discharge and charge equally and have a longer service life. Between the battery terminals or battery terminals and distribution points, the cables should be an equal length, same wire size, as short as possible and sized large enough to prevent significant voltage drop of 0.075 volts (75 millivolts) per 100 amps or less in the cables and connectors. Battery cables to the charger or inverter (or other large load) should be of equal length and wire size so the batteries will charge or discharge evenly. What is important is that the battery manufacturer's recommended charging voltages are being applied directly across the battery's terminals from the charging source. Using an adjustable Low Voltage Disconnect set to a minimum of 10.5 VDC (12.0 VDC is better) will insure a lower average Depth-of-Discharge and will protect electrical and electronic appliances and the batteries from damage from a real deep discharge and cell reversals.

7.3.3. Which is Better, Two 6-volt Batteries in Series or Two 12-volt Batteries in Parallel?

Some battery experts believe that batteries in series are easier to discharge or charge because the same amount of current is applied to each cell and, with fewer cells, are a little more reliable. Other battery experts believe that batteries in parallel are better because they require less space, will have more capacity due to the Peukert Effect and if a cell should fail open, the bad battery can be disconnected and the other one can continue to be used. For additional information on this discussion, please read Collyn River's excellent article on Interconnecting Batteries, Ample Power's Parallel Batteries?, and Battery Configuration: Parallel or Series? published by Sierra Nevada Airstreams.

7.3.4. How Do I Increase the Voltage?

If more voltage is need, connect identical batteries in series in the following manner:

Batteries In Series

Two identical 6-volt batteries can be connected in series to produce 12-volts. Two identical 12-volt batteries or three identical 8-volt batteries can be connected in series to produce 24-volts. Three identical 12-volt batteries connected in series or six identical six-volt batteries will produce 36-volts and so on. Please note that the total amp hour capacity remains the same. Other voltage combinations are possible, but the battery type and amp hour capacity of each of the batteries in series should be the same because uneven discharging will cause charging problems.

You could also use a DC-to-DC Converter to produce different or constant DC voltage. A common problem is powering a laptop computer or other appliance requiring more than 14 VDC from a 12-volt battery or 12-volt appliances from 24, 36 or 48-volt battery banks. Using an efficient DC-to-DC Converter is highly recommended, automatic and eliminates the problems associated with wide voltage variances from uneven multi-battery discharges and recharges.

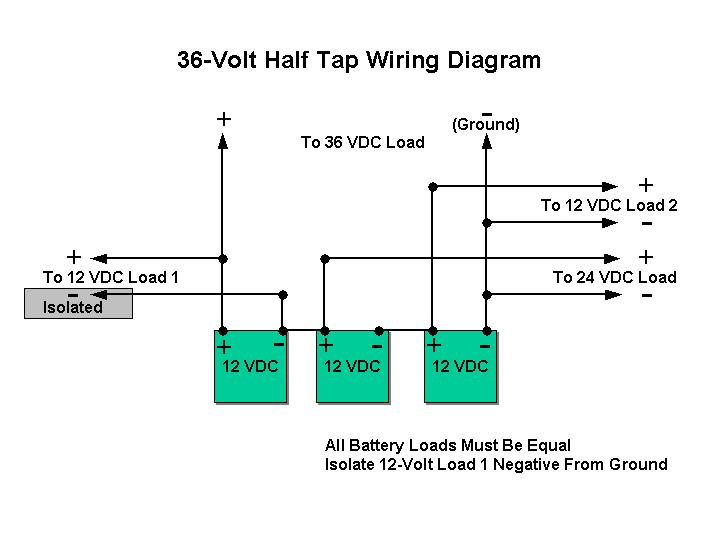

7.3.5. How Can I Reduce the Voltage?

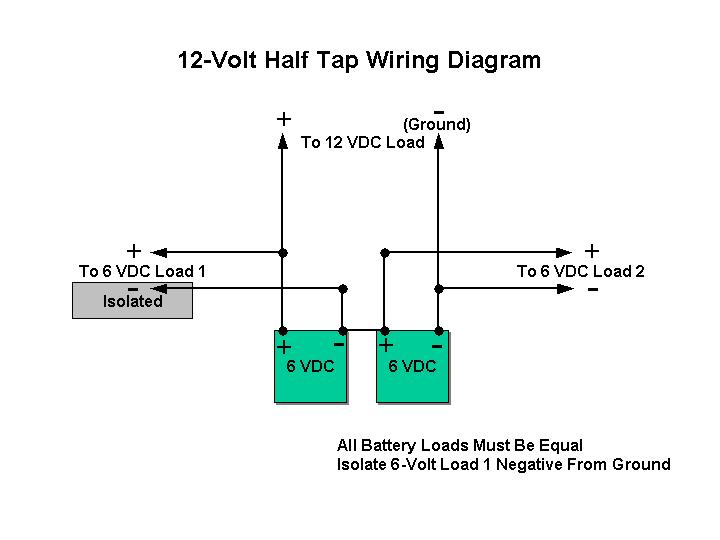

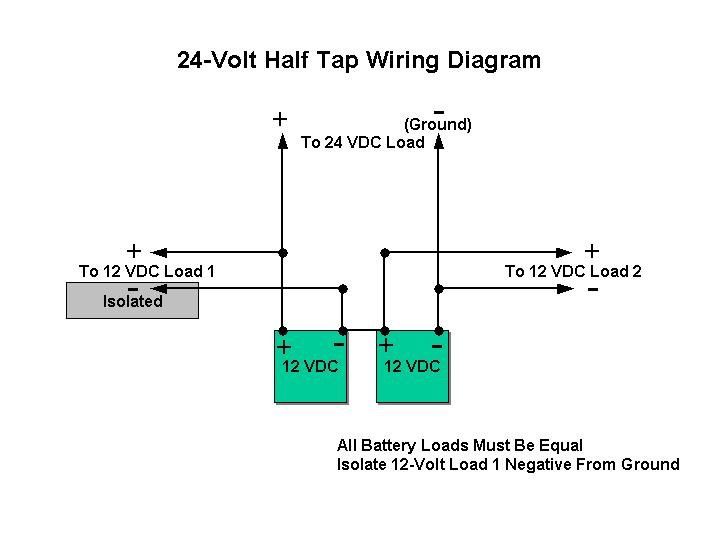

"Half-tapping" two batteries in series can be used to produce a source with half of the voltage, three batteries for one third and two thirds the voltage, and so on. For example and using the diagram below, let's assume that two identical 12-volt batteries are used in series to power a 24-volt trolling motor and there is a requirement to power 12-volt lights or electronic equipment. The 12-volt electrical appliances can be connected to the 12-volt batteries as long the 12-volt electrical loads are equally divided between the two 12-volt batteries, so the loads are balanced and fused. (In the diagrams below, the negative connection for Load 1 must be isolated from "ground" because it will place a dead short on the Battery for Load 2.) If batteries connected in series are discharged unequally, recharging the batteries with a single bank charger (a 24-volt charger in this example) will cause the battery (or cell) with the lowest capacity will overcharge or over discharge. Over time, this will significantly reduce the battery's service life. Collyn Rivers' article 12 volt Systems From 24 Volt Supplies has more options.

A better solution is to use a 24-volt to 12-volt DC-to-DC Converter or a separate 12-volt charging system and battery to produce 12-volts because an unbalanced load will not occur on the batteries and voltage variances. With batteries in series, if discharging unevenly or use of non-identical batteries can not be avoided, then use an isolated multi-bank charger, single bank charge with an external diode isolator (adjusted for the voltage loss), or combiner to recharge all of the batteries at the same time.

Below are examples of wiring diagrams of "half tapped" 12-volt, 24-volt, and 36-volt battery banks.

7.3.6. Which Weighs More--One 12-volt or Two 6-volt Batteries?

With equal amp hour capacities, a single 12-volt battery will weigh approximately 10% less than two six-volt batteries connected in series due to the additional case material and the battery connecting cable. But, the two six-volt batteries can be split apart and each battery weighs approximately half of the weight of the 12-volt battery and is easier to transport.

7.3.7. Can I Mix Old and New or Non-Identical Batteries?

To prevent charging problems when connecting batteries in series or series-parallel, do not mix old and new batteries, ones of different capacities or types. Mixing old batteries with new batteries is like mixing old milk with new milk--soon you have nothing but old milk. The weakest or smallest capacity battery (or cell) connected in series or series-parallel will over discharge and overcharge, which will eventually cause a premature failure. If replacing the weakest batteries occurs, "preconditioning" the new batteries is recommended by charging and discharging several cycles. If discharging the batteries unevenly or use of non-identical batteries has to occur, then use an isolated multi-bank charger, single bank charger with an external diode isolator (adjusted for the voltage loss), multiple chargers, or combiner to recharge the batteries all at the same time or recharge each battery separately. Batteries that will not produce at least 80% of their rated amp hour capacity are considered to be bad and should be replaced. Historically once a battery will not produce 80% of it's rated capacity, the failure rate goes up exponentially.

In North America, manufacturers build their batteries to an adopted Battery Council International (BCI) Group Size Number (U1, 24, 27, 31, 34, 35, 65, 75, 78, 8D, GC, L-16, etc.) standard. These specifications, which are based on the physical case size, terminal placement, type and polarity. In Europe, the European Committee for Standardization has adopted the ETN (European Type Numbering) standard to replace the older EN, IKC, Italian CEI, and German DIN standards. An ETN number (Battery Identification - BS EN 60095) is divided into three groups. The three digit first group is the voltage and amp hour capacity. For numbers below 500, the number is the amp hour capacity rating and a six-volt battery. For numbers above 500, subtract 500 from the number and that is the amp hour capacity for a 12-volt battery. The second three digit group indicates the battery's physical case size, case base hold down, type and layout of terminals (poles), and polarity. The third three digit group determines the EN cold cranking current in amps multiplied by 10. In Asia, the Japanese JIS standard is commonly used and in Russia GOST 959 is used.

The OEM battery number is a good starting place to determine the replacement battery size. Within a size, the CCA and RC ratings, warranty and battery type will vary within models of the same brand or from brand to brand. Batteries are generally sold by model or series, so the size numbers will vary for the same price. For the same price, potentially a physically larger battery with more CCA or RC (or AH) can be purchased than the battery being replaced. For example, a 34/78 group might replace a smaller 26/70 group and give an additional 30 minutes of RC. If you buy a physically larger battery, be sure that the replacement battery will fit, the cables will connect to the correct terminals, and that the terminals will NOT touch metal surfaces such as the hood when it is closed.

The battery manufacturers publish application Selection Guides that contain OEM cold cranking amperage requirements and group number replacement recommendations by make, model and year of car, battery size, and CCA and RC (or Amp Hour) specifications. You can also find the BCI size information online at http://www.rtpnet.org/~teaa/bcigroup.html or in some of the Selection Guides in the Battery Manufacturers and Private Labels List found at http://www.batteryfaq.org. Manufacturers might not build or the store might not carry all the battery sizes. To reduce inventory costs, dual terminal "universal" batteries that will replace several group sizes are becoming more popular and fit 75% or more of cars on the road today.

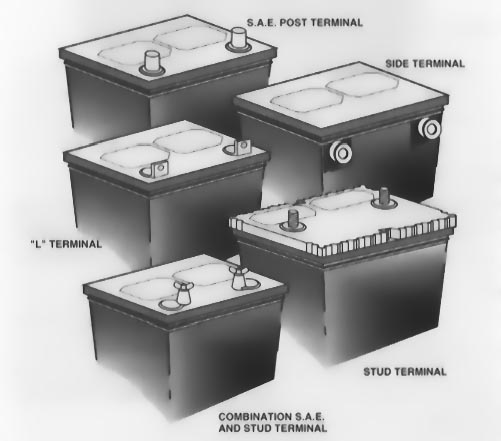

There are six types of common battery terminals: SAE Post, GM Side, "L", Stud, combination SAE and Stud, and combination SAE Post and GM Side. For automotive applications, the SAE Post is the most popular, followed by GM Side, then the combination "dual" SAE Post and GM Side. "L" terminal is used on some European cars, motorcycles, lawn and garden equipment, snowmobiles, and other light duty vehicles. Stud terminals are used on heavy duty and deep cycle batteries. The POSITIVE (+) SAE terminal post is slightly larger, 1/16 inch (1.6 mm), than the NEGATIVE (-) post. Terminal types, locations and polarity will vary. There are adapters available that will you allow to connect cables with "GM" style side terminals to batteries with top post terminals or visa versa. Additional terminals for deep cycle batteries can be found on http://www.usbattery.com/pages/usbterminals.htm. Lugs are the connectors on the ends of battery cables that connect to the terminals on the battery.

[Source: BCI]

Battery manufacturers or distributors will often "private label" their batteries for car manufacturers, large chain stores or export. An alphabetical list of most of the largest battery manufacturers/distributors, their Web addresses, telephone numbers and some of their brand names, trademarks and private labels can found in the Battery Manufacturers & Private Labels List on the http://www.batteryfaq.org/ Web site. Ownership, branding, Web addresses and telephone numbers will sometimes change.

Lead-acid batteries are perishable and sulfate in storage due to their natural self discharge, especially in temperatures above 80° F (26.7° C). Please see Section 16 for more information on sulfation.

Determining the "freshness" of a battery is sometimes difficult. Unless it has been periodically recharged or is "dry charged" (shipped without electrolyte), NEVER buy a wet Standard (Sb/Sb) or Low Maintenance (Sb/Ca) battery that is MORE than three months old or a wet "Maintenance Free" (Ca/Ca) battery that is MORE than six months old. Dry charged batteries are shipped without electrolyte, but usually have "sell by" dates of one to three years. Depending on the temperature, AGM (Ca/Ca) and Gel Cell (Ca/Ca) batteries that can be stored six to 18 months before the State-of-Charge drops below 80%. Please see Section 16. for more information on sulfation. Dealers will place their older batteries in storage racks so they will sell first and they do not have to maintain them. The fresher batteries can be found in the rear of the battery rack or in a storage room. For a wet battery, the date of formation is often stamped on the case or printed on a sticker. If at all possible, have a new battery tested, and recharged if necessary, before the battery leaves the store. This can save a lot of time and frustration if the new battery is sulfated or has a manufacturing defect.

Some of the manufacturer's formation date coding techniques are as follows:

7.6.1. Delphi (ACDelco) and some Sears DieHard

Dates are stamped on the cover near one post. The first number is the year. The second character is the month A-M, skipping I. The last two characters indicate geographic areas. For example, 0BN3=2000 February.

[Source: Interstate Batteries]

7.6.2. Douglas

Douglas uses the letters of their name to indicate the year of manufacture and the digits 1-12 for the month, D=1994 O=1995 U=1996 G=1997 L=1998 A=1999 S=2000. For example, S02=2000 Feb.

7.6.3. East Penn, Exide (Champion), Johnson Controls Inc., Interstate, Chrysler (Mopar) and some Sears DieHard)

Usually on a sticker or hot-stamped on the side of the case. A=January, B=February, and the letter I is skipped. The number next to the letter is the year of shipment. For example, B0=Feb 2000.

[Source: Interstate Batteries]

7.6.4. Exide (some Sears non-Gold DieHards)

The fourth or fifth character is the month. The following numeric character is the year. A-M skipping I. For example, RO8B0B=February 2000.

[Source: Interstate Batteries]

7.6.5. Optima

The first character is the year. The following three numeric characters are the days of the year. For example, 3123=3 May 2003.

7.6.6. Trojan

The date code on the negative post is stamped as the battery comes off of the finishing line, ready to ship out or go into stock. The code that is stamped is usually one month ahead. Therefore, a battery that comes out in March will carry an April date code. The code on the positive post is the manufacturing date that indicates when the battery was physically built but before the addition of any electrolyte. The letter is the month (A=Jan, B=Feb, C=March, etc.) and the number is the actual date. So "K26" means that the battery was ready for electrolyte filling and the first forming charge was on November 26th. Since the negative post shows A2 (January 2002), the manufacturing year has to be 2001.

7.6.7. Concorde

The activation date is found on an orange sticker on the shipping carton or email Concorde Customer Service with the serial number of the battery.

7.6.8. Rolls and Surrette

The four digit date code represents the day of the week (first digit), week of the year (middle two digits) and the year (last digit). For example, April 4, 2003 would have 4143 as a date code. The date code is stamped into the front edge of the cover of the battery.

7.6.9. U.S. Battery

The three digit date code represents the year (first digit), month (middle letter) and the plant code (last digit). For example, April, 2003 would have 3Dx as a date code. The date code is stamped into the positive terminal of the battery when it is formed. The characters burned into the case are the production run. For example A270N.

7.6.10. Other Date Coding Methods

The four digit date code could represent the week of the year (first two digits) and the year (last two digits). For example, November 1, 2006 would have 4406 as a date code. The four digit date code could also represent the month of the year (first two digits) and the year (last two digits). For example, November 1, 2006 would have 1106 as a date code. The six digit date code could represent the month of the year (first two digits), day of the year (middle two digits), and the year (last two digits), or any other combination. For example, November 1, 2006 would have 110106 or 011106 as a date code. The date code is usually stamped into battery or printed on a sticker attached to the battery.

If you cannot determine the date code, ask the dealer or contact the distributor or manufacturer. Because of permanent sulfation due to self-discharge, a fresher battery is definitely better and does matter.

Battery warranties are not necessarily indicative of the quality or service life. Some dealers will prorate warranties based on the list price of the bad battery, so if a battery failed half way or more through its warranty period, buying a new battery outright might cost you less than paying the difference under a pro rated warranty. The exception to this are the free replacement warranties. They represent the risk that the manufacturer is willing to assume. A longer free replacement warranty period is generally better depending on the cost of the battery.

The following are some tips for consumers for buying car, motorcycle, truck, marine and recreational vehicle starting and deep cycle batteries. Before you buy a replacement battery, you should fully charge your old battery, remove the surface charge and test it. You could have a faulty charging system, loose alternator belt or corroded terminals and the old battery is good but was just discharged.

7.8.1. Physical size matters!

Purchasing a battery has become much easier because most of the battery and vehicle manufacturers have adopted the BCI Group Number, European Type Number (ETN) which replaces DIN or JIS as a standard for the battery's voltage, physical size, and terminal type and location. Web based Battery Replacement Selectors or Fitment Guides published by battery manufacturers or distributors can make the task even easier. They contain the vehicle's minimum cold cranking amps (CCA) requirement and battery size replacement recommendations by make, model and year of manufacturer.

7.8.2. Pick the battery type that matches your charging system.

For starting an engine, using a car or starting battery is normally a better choice than a deep cycle battery because it is specifically designed for shallow (1%-3%) discharges. The battery type MUST match the vehicle's charging system or the new battery or charging system could be damaged. The easiest way to accomplish this is to replace your battery with the same or compatible type of battery that was originally installed by the vehicle's manufacturer. The exception to this is in hot climates, using a non-sealed wet car battery (with filler caps) is highly encouraged because lost water can be easily replaced. For batteries with side terminals commonly found in General Motors vehicles, check the terminal bolt length and do not over-tighten because you might crack the battery case and cause a leak.

For a deep cycle application, using a deep cycle battery is much better alternative than using a starting battery because the deep cycle battery will have a much longer service life when deeply discharged because the plates are thicker.

7.8.3. For car batteries, select the battery with CCA (Cold Cranking Amps) that will meet (or just exceed the vehicle manufacturer's recommendation), or is best suited for the coldest temperatures encountered in your climate. This is because more CCA requires greater plate surface area and in order to fit more surface area in the same space, this means thinner plates. Thinner plates will normally cause shorter overall service life. Do not substitute CA (Cranking Performance Amps), MCA (Marine Cranking Amps), or HCA (Hot Cranking Amps) for CCA. In hot climates, buying batteries with double or triple your vehicle's cranking amp requirements is a waste of money. Unless starting batteries are used in extremely cold climates, increased CCA is required to crank a sluggish engine and the over come the inefficiency of a cold battery. James W. Douglas' recommendation in his February 2000 article, Battery Selection--A Consumers Guide, in The Battery Man magazine, is:

"The sleek, aerodynamic designs have low cooling airflow through the engine compartment and that small in stature battery with high cold crank [amps] will have many very thin lead plates just to get the necessary surface area to make that big cold crank number. It will have the lower volume of electrolyte to provide the cooling necessary for long life and the greater capacity to run the [electrical] systems on the car. All of those thin plates will corrode away and fail long before expected putting the high performance battery's life below that of the lower CCA rated battery with the lower cost. Your best rule-of-thumb is, if it meets the OEM (Original Equipment Manufacturers) recommendation, buy it. Look for the highest reserve capacity [RC] battery at the correct CCA (Cold Cranking Amps)."

7.8.4. More Reserve Capacity (RC) or Amp Hours (AH) is a good thing.

Greater RC or AH is better because of the effects of increased parasitic (ignition key off) loads, normal battery self discharge while the vehicle is not being used, and the demands of stop-and-go city driving. Amp Hour (AH) ratings are normally used to describe the capacity of deep cycle and European car (starting) batteries. When comparing AH specifications, use the same discharge rates, expressed in hours. The most common is the 20 hour rate which is expressed as "C/20". It is the rate of discharge so a fully charged battery is discharged over a 20 hour period. For example, a 100 AH battery discharged at 5 amps per hour will take 20 hours to become discharged. If two batteries have the same capacity, the heavier battery has more lead and is normally better choice.

Batteries are generally sold by model or series, so the battery sizes can vary for the same price. This means that for the same price, potentially a larger battery with more RC (or Amp Hours) than be purchased than the battery being replaced. If a physically larger battery is bought, be sure that the replacement battery will fit, the cables will connect to the correct terminals, and that the terminals will NOT touch metal surfaces such as a closed hood (or bonnet).

7.8.5. Batteries are perishable, so buy the FRESHEST available.

Unless a battery has been periodically recharged, never buy a non-sealed wet Standard (Sb/Sb) or Low Maintenance (Sb/Ca) battery that is more than three months old, a sealed wet "Maintenance Free" (Ca/Ca) battery that is more than six months old, or sealed AGM (Ca/Ca) or Gel Cell (Ca/Ca) VRLA battery that is over 12 months old, because it may have some permanent sulfation and lost some capacity. "Dry charged" batteries are shipped and stored without electrolyte. The electrolyte is added and initially charged by the dealer or the buyer. They usually have "sell by" dates of one to three years. Battery dealers will often place their fresher batteries in the rear of the battery rack or in a storage room. The date of manufacture is often stamped on the case or printed on a sticker. If possible, have a new battery tested to insure it meets or exceeds it's advertised specifications, and recharged if necessary, before it leaves the store.

7.8.6. Look for longer free replacement warranties.

Pro rated battery replacement warranties or cost are not necessarily indicative of the quality over the life of the battery. The exception is the free replacement warranty, which represents the risk that the dealer, distributor, or manufacturer is willing to assume.

7.9. How Do I Size The Components For Backup AC Power?

For AC backup power, here are the basic steps for sizing the deep cycle battery bank, inverter, AC battery bank charger and generator based on your AC power requirements. Deep Cycle battery bank capacity sizing is based on power requirements, inverter efficiency, wiring power loss, discharge rate (or Peukert Effect), electrolyte temperature, and desired average Depth-of-Discharge. DC to AC Power Inverters has a simple and easy to use battery capacity calculator at http://www.dcacpowerinverters.com/faq.htm#22. Please note that microwave ovens can have very large loads and might not be suitable for inverter or battery operation.

7.9.1. Calculate the cumulative daily AC load in amps hours (AH) at 120 VAC. This will require determining how much current an appliance uses and for how long times the "duty cycle" (the amount of time the appliance is on during that time period). The label of the electrical appliance will have the amount of power and the voltage that the appliance uses. Power is expressed either in watts or in amps. If wattage is given, divide it by the voltage to convert to the number of amps.

For example:

a. Two 60 watt lights that you use continuously for four hours, the calculation would be 60 watts/120 volts = .5 amps and .5 amps x 4 hours x 2 lights = 4 Amp Hours @ 120 VAC.

b. A 200 watt refrigerator that is on for 24 hours with a 25% duty cycle, the calculation would be 200 watts / 120 volts = 1.67 amps and 1.67 amps x 24 hours x 25% duty cycle = 10 Amp Hours @ 120 VAC.

c. A five amp power drill that you use 15 seconds at a time for 25 times, the calculation would be 5 amps x 15 seconds/60 seconds/60 minutes x 25 times = .52 Amp Hours @ 120 VAC.

d. A 10 amp sump pump that is on 24 hours and has a 50% duty cycle, the calculation would be 10 amps x 24 hours x 50% duty cycle = 120 Amp Hours @ 120 VAC.

The total daily usage of these four appliances would be 4 AH + 10 AH + .5 AH + 120 AH = 134.5 Amp Hours @ 120 VAC per day.

7.9.2. Depending on the efficiency of the inverter and the power loss in the wiring, it takes between 12 and 14 amps of 12 VDC power to produce one amp of 120 VAC power or 24 to 28 amps to produce one amp of 240 VAC. Using the above example in the worst case, the usage would be 14 x 134.5 AH = 1883.3 Amp Hours per day @ 12 VDC.

7.9.3. Depending on the average load on the battery bank, the total daily usage may have to be adjusted due to the Peukert Effect. Deep cycle batteries are normally rated by the fully charged capacity divided by the number of hours of discharge it take to drop to 10.5 VDC. A very common rate is over a 20 hour period and is expressed as "C/20". In the example above, 1883.3 AH are being consumed in a 24 hour period which is a slightly lower rate than over a twenty hour period, so we could probably decrease the daily usage by 10% or 1883.3 AH x .9 = 1695 AH per day. If all of this power were consumed over six hour period, you would probably need to increase the daily usage by approximately 25%.

7.9.4. Depending on the temperature of the battery electrolyte, the usage might also have to adjusted. The example above assumes 80 degrees F. If your battery bank was operating at 60 degrees F then you would have to increase the usage by 10% and at 32 degrees F, by 20%. Let us assume the batteries are in a heated area at 70 degrees, so you would increase the daily usage by 5% or 1695 AH x 105% = 1780 AH per day.

7.9.5. Depending how many discharge/charge cycles you want your battery bank to last, you will need to increase the usage. Let's assume that you are fully recharging the battery bank daily and using "low end" inexpensive deep cycle batteries that when fully discharged (or 100% average Depth-of-Discharge) will last 50 cycles, at 80% average DoD (or 20% State-of-Charge) will last 200 cycles and at 50% average DoD will last 500 cycles. In this example, for 100% average DoD, you would require a battery bank with a capacity of 1780 AH to provide for 1780 AH of daily usage, at 80% DoD (1780 AH / 80% = 2225 AH), and at 50% DoD (1780 AH / 50% = 3560 AH). However, you would have to replace the smaller, less expensive battery bank every 50 cycles.

You can determine the optimum battery bank size by multiplying the number of cycles time the total amp hour capacity divided into the cost. For a simple example, let's assume that a 225 Amp Hour (C/20) 12-volt deep cycle battery costs $85. At 100% DoD, 1750 AH / 225 AH per battery = 8 batteries x $85 per battery = $680 total cost and 50 cycles x 1780 AH = 89,000 total AH. So $680 / 89,000 = .764 cents per amp hour. At 80% DoD, the calculation would be 2225 AH / 225 AH per battery = 10 batteries x $85 per battery = $850 total cost and 200 cycles x 2225 AH = 445,000 total AH. So $850 / 445,000 = .191 cents per amp hour. At 50% DoD, the computation would be 3560 AH / 225 AH per battery = 16 batteries and 16 batteries x $85 per battery = $1360 total cost and 500 cycles x 3560 AH = 1,780,000 total AH. So $1360 / 1,780,000 = .076 cents per amp hour. In this example, a larger, more expensive battery bank with a lower average 50% DoD will cost approximately one tenth the cost of fully discharging the battery bank (100% DoD) every cycle. This example does not take into consideration the additional maintenance, cabling cost, cost of money, etc. that would be used in a Total Cost of Ownership determination.

7.9.6. Once you have determined your daily capacity, then you need to determine how many hours or days you want to run using your battery bank before you recharge your batteries and decrease or increase the size of the battery bank accordingly. Please see Section 9 for more information on charging.

7.9.7. To size the inverter (or inverter portion of an inverter charger using the example above, calculate the worst case load (with all the appliance on at once) which is (60 watts x 2 lights) + 200 watts + (5 amps x 120 volts) + (10 amps x 120 volts) = 2120 watts @ 120 VAC. Be sure to consider the start surge power requirement of up to five time the run current with large inductive starting loads, such as microwave ovens, motors and transformers. Some "square wave" or "modified" sine wave inverters are not capable of providing the power to run some motors, compressors or other electronic or electrical appliances. In these cases, a "true" sine wave inverter must be used. For more information on power inverters, please see Don Rows' Frequently Asked Questions about Power Inverters.

7.9.8. To size the battery charger (or charger portion of an inverter charger), you will need the output to be at least 12% of the battery capacity used to fully recharge the batteries within 24 hours. Using the example above, you would need at least a 214 amp charger to replace 1780 AH in 24 hours.

7.9.9. To size an AC generator, using the example above without recharging the battery bank, the worst case load (with all the appliance on at the same time) is (60 watts x 2 lights) + 200 watts + (5 amps x 120 volts) + (10 amps x 120 volts) = 2120 watts @ 120 VAC. You would also need to consider the surge power requirement up to five times the run load. If you are using motors, take into consideration their peak starting current. If the batteries need to recharged the batteries in addition to using the appliances, add 214 amps/12 DC amps per AC amp = 17.8 amps @ 120 VAC and 17.8 amps x 120 volts = 2140 watts @ 120 VAC to power the battery charger. So, to power both the load and recharge the batteries, a generator with a capacity of 8000 to 12000 watts @ 120 VAC in required depending on the surge of the pump motor and battery charger.

As can be seen from this example, using just battery backup for one day for AC power with a heavy load can become very expensive, so that is why most "grid" or commercial AC power backup systems is an AC generator, combination of batteries and AC generator, or combination of battery and solar power with AC generator backup.

7.10. How Do I Size Battery Banks?

For additional information on deep cycle battery bank sizing can be found, please see Glacier Bay Refrigeration's HOW TO SIZE AND USE YOUR BATTERY BANK, Constian von Wentzel's Sizing a Lead-Acid Battery Bank, or Optima's Marine [and RV] Calculation Information. To calculate the ampere draw for trolling motors based on the pound thrust of the motor, divide the pounds of thrust by the motor voltage and multiply by 12. For example, 40 pound thrust motor at 24-volts will draw approximately 20 amps. Information on splitting battery banks can be found in Chris Gibson's article on http://www.smartgauge.co.uk/splitting.html.