[Source: Vintage Triumph Register]

Last Updated on October 28, 2007

5.1. How Does A Vehicle Charging System Work?

Charging System Functional Diagram

Vehicle Charging Voltage Graph

5.3. What If I Cannot Keep My Battery Charged and the Battery Tests OK?

5.4. How Can I Test To Determine If Charging System Is Large Enough?

5.1. How Does A Vehicle Charging System Work?

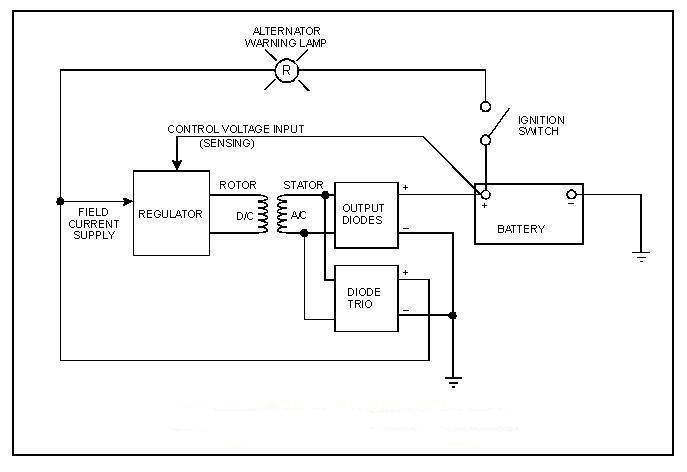

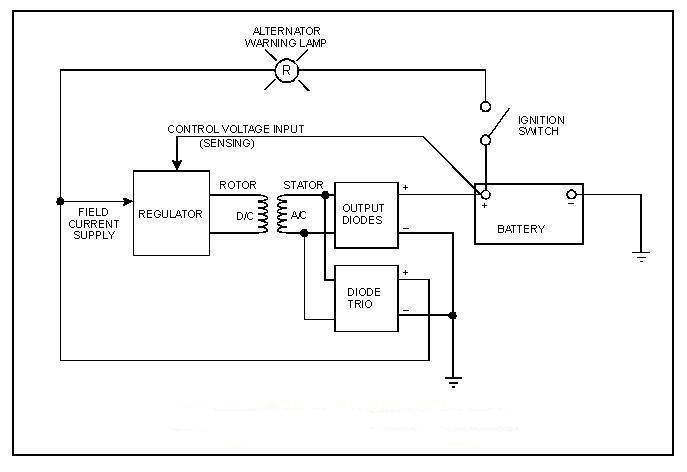

Referring to Dan Masters' diagram below, a vehicle's charging system is composed of an alternator (or DC generator), voltage regulator, battery, and indicator light or gauge. A good source of information on the basics of vehicle charging systems can be found on Perry Babin's Basic Car Audio Electronics Web site at http://www.bcae1.com/charging.htm. A detailed description of how and alternator works is in Nathen Eagle's article Using an Alternator in Renewable Energy Projects or Bob Hewitt's article Alternators - what are they, how do they work and what breaks??.

While the engine is running, the charging system's primary purpose is to provide power for the car's electrical load, for example, ignition, lighting, audio system, accessories, etc., and to recharge your vehicle's battery. The alternator's output capacity is directly proportional to the RPM of the engine and alternator temperature. Charging systems are normally sized by the car manufacturers to provide at least 125% (when operating at high RPM) of the worst-case OEM (Original Equipment Manufacturer) electrical load, so that the car battery can be recharged. That is the reason that short, stop and go driving at night or in bad weather might not keep the battery fully recharged, especially if the electrical load has been increased with after market accessories, such as high power audio equipment, lighting or an electric winch. Vehicle charging systems are not designed to recharge fully discharged batteries and doing so may damage the stator or diodes from overheating.

CHARGING SYSTEM FUNCTIONAL DIAGRAM

[Source: Vintage Triumph Register]

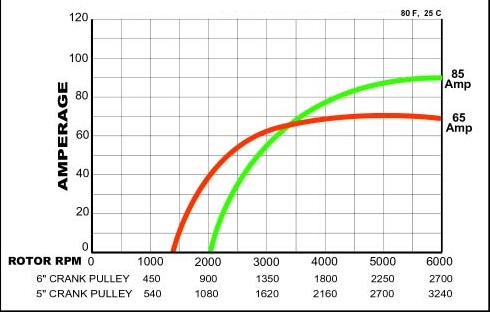

In the Balmar Alternator Output diagram below, the power output curves are shown for 65 amp and 85 amp alternators. Note that the 65 amp alternator in this example produces more current output (power) at a lower RPM that does the larger alternator until approximately 3300 RPM. Also note the difference that the crankshaft pulley size makes. A larger crankshaft pulley will create a higher alternator RPM, thus causing the alternator to produce more power at a lower engine RPM.

ALTERNATOR OUTPUT GRAPH

[Source: Balmar]

When the charging system fails, usually a "battery" or "alternator" warning indicator or light will come on or the voltage (or amp) gauge will not register "good". If you increase the engine speed and the alternator light becomes brighter, then the battery needs to be fully recharged and tested. If the light becomes dimmer then the problem is most likely in the charging system. Another simple charging system test is with the engine running shine the headlights against a wall at night. If you turn the engine off and the lights get dimmer, then the charging system is producing a higher voltage. If the light becomes brighter, then you probably have a charging system problem. The indicator (also known as an "idiot") light is a direct comparison between the voltage output of charging system and the voltage output of the battery. The next test requires use of a known-to-be-good, fully charged battery. Temporarily replace the old battery with this battery and run the engine at 2500 RPM or more for two minutes. Depending on the load and ambient temperature, the voltage should increase to between 13.0 and 15.1 volts during this period. Most vehicles with good charging systems will measure between 13.8 and 14.8 volts on a warm day, depending on the battery type that the charging system was designed for.

Some automotive charging system designers prefer lower absorption voltages, for example 13.8 VDC, to reduce water consumption and wet Low Maintenance (Sb/Ca) starting batteries to reduce cost. Over time, this combination tends to undercharge the battery and to cause electrolyte stratification which causes the battery to gradually loose capacity due to an accumulation of lead-sulfate or premature failures. One solution is to periodically recharge the battery with an external charger to remove the sulfation or to increase the absorption voltage output to the battery as described by Chris Gibson on http://www.smartgauge.co.uk/alt_mod.html. Other solutions are to use an adjustable or "smart" voltage regulator, add resistance to the "sense" lead to the regulator (if equipped), or equalize the battery. Increasing the absorption voltage or equalizing will increase water consumption in wet batteries, so the electrolyte levels will need to be checked more often.

As in the Bosch Voltage Regulator example below, most voltage regulators are temperature compensated to properly charge the battery under different environmental conditions. As the ambient temperature decreases below 77° F (25° C), the charging voltage is increased to overcome the higher battery resistance. Conversely, as the ambient temperature increases above 77° F (25° C), the charging voltage is decreased. Other factors affecting the charging voltage are the alternator temperature, battery's condition, State-of-Charge (SoC), sulfation, electrical load and electrolyte purity.

VEHICLE CHARGING VOLTAGE GRAPH

[Source: Bosch]

If a battery terminal's voltage is below 13.0 volts with the engine running and the battery tests good after being recharged or if you are still having problems keeping the car battery charged, then have the charging system's output voltage and load tested. Also, have the car's parasitic load, the electrical load with the ignition key turned off, tested. (Please see Section 10.) A slipping alternator belt or open diode will significantly reduce the alternator's output capacity. If the output voltage is above 15.1 volts with the ambient temperature above freezing, if the battery's electrolyte levels are frequently low, "boiling", or if there is a "rotten egg" odor present around the battery, then the battery is being overcharged and the vehicle's charging system should be tested.

5.2. What If My "Battery" or "Alternator" Light Is On? (Or the Gauge Is Not Showing a "Charging" Condition?)

The "Battery" or "Alternator" light is an indication that there is a significant mismatch between the voltage that the charging system is producing and the battery voltage. Some vehicles use a voltmeter or current meter to indicate if the charging system is working. The battery and charging system must work together to provide the electrical power for the vehicle and to keep the battery recharged so it can restart the engine. The most common causes, in the order of priority, are:

If the electrolyte levels, alternator belt is OK and the battery terminal connections are free from corrosion, then take your vehicle to an auto parts or battery store, and have the battery and charging system tested (highly recommended) or use the troubleshooting guide above. In the United States and Canada, some stores like Auto Zone, Sears, Wal-Mart, Pep Boys, etc., will test them for free. One of the first three simple faults in the list above has caused many a good battery to be replaced. A new battery can cause a weak alternator or starter to fail.

5.3. What If I Cannot Keep My Battery Fully Charged and the Battery Tests OK?

The vehicle's electrical load is normally satisfied first by the charging system and then any remaining power is used to recharge the battery. For example, if the total electrical load is 14 amps and the charging system is producing 35 amps at 2500 RPM, then up to 11 amps will be available for recharging the battery, which will take approximately six minutes. If the charging system is operating at say a maximum capacity of 90 amps at 5000 RPM, then the battery usually will be recharged within two minutes. Now let us assume that the engine is idling and the charging system is only capable of producing 10 amps. Four amps from the car battery are required to make up the difference to satisfy the 14 amp electrical load and the battery is being discharged further. This is why making short trips, driving in stop-and-go traffic, or during bad weather when there is a heavier electrical load, the starting battery may never get recharged and may even become "completely" discharged.

Using the example above, let's assume that an after-market, 400 watt @ 69% efficiency high-power audio system, 20 amp electric winch, or 276 watts of lights is installed that adds an additional 20 amps of load. To covert power amplifier wattage into amps, multiply the amplifier's watts by .5 to .85 (depending of the efficiency of the amplifier) and then divide by the operating voltage. To convert winch motor or lighting power (in watts) to amps, divide the watts by the operating voltage. With a total electrical load of 34 amps, at RPM below 2500, the battery will never be recharged with an 90 amp system. While the engine is running in this case, the battery must make up the deficit. The solution is to upgrade the charging system to 125% or more of the new worst-case load. In this example and based on stop-and-go driving habits, a high output charging system capable of 105 amps or more would be required to keep the battery fully charged. High alternator temperatures can further reduce the maximum output of a charging system, so cooling and sizing based on the continuous load matters. Heat kills alternators, so Bosch, for example, has water cooled models available.

For boat owners, Balmer recommends that alternator(s) be sized to 25% of the batteries' total capacity for wet batteries and 35% to 40% for AGM (Ca/Ca) and Gel Cell (Ca/Ca) VRLA batteries. Alternator belt sizing is also important. A single 3/8" belt will drive an alternator up to 80 amps, 1/2" up to 110 amps, and multiple belts for over 110 amps. Ample Power provides an excellent Troubleshooting the Alternator System guide.

5.4. How Can I Test To Determine If Charging System Is Large Enough?

A simple test to determine if the charging system is large enough is to check the battery's State-of-Charge after the surface charge has been removed. If the State-of-Charge is consistently above 95%, then the charging system is fully recharging the car battery based on your driving habits and electrical load. If is is consistently below 80%, then you will want to consider upgrading your charging system to produce more current. There are several possibilities to increase the capacity of your charging system to include changing the pulley diameters, replacing the alternator with an higher output model, adding a second charging system (for a dual battery set up), replacing the voltage regulator, etc. An auto electric or alternator rebuilding shop can assist you. If the State-of-Charge is inconsistent, the you might consider using a temperature compensated, "smart" charger with a quick disconnector to "top off" your battery. If you have a heavy electrical load while the engine is not running, install a dual or multi-battery system with the heavy load on a deep cycle battery bank. If consistently undercharged or overcharged, a lead-acid battery will lose capacity and prematurely fail.